Wholesale Quality Floor Mats - Trusted Supplier for Durable Floor Solutions

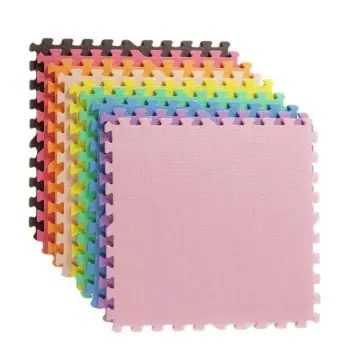

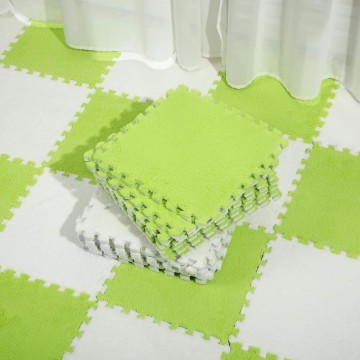

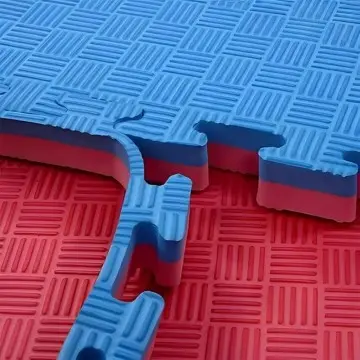

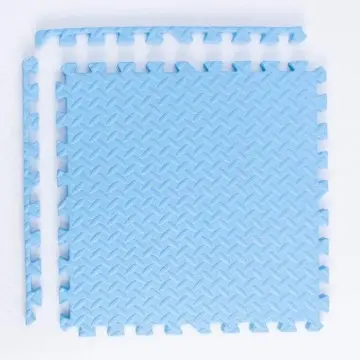

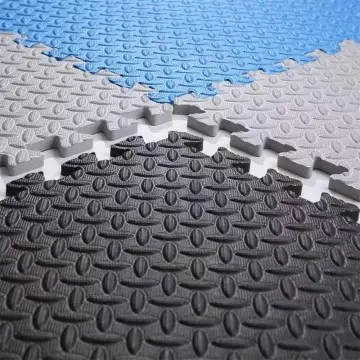

As a premier manufacturer of floor mats, we cater to businesses seeking top-quality products at competitive prices. Our Floor Floor Mat Factory specializes in bulk wholesale solutions across various industries. We are dedicated to excellence, producing durable and versatile floor mats designed to endure heavy foot traffic while enhancing the visual appeal of your space. Utilizing premium materials and cutting-edge manufacturing techniques, each mat is crafted to serve its purpose effectively while adding value to your workspace. Partnering with Guangxi Hongle Plastic Products Co., Ltd. ensures you gain reliability and quality backed by our extensive expertise. Our products are ideal for improving safety in your facility and elevating your brand's image. Contact us for customized solutions tailored to your specific requirements.

Methods To Floor Floor Mat Factory More Than a Supplier - A Partner From Concept to Delivery

Methods To Floor Floor Mat Factory More Than a Supplier - A Partner From Concept to Delivery

| Stage | Description | Key Activities | Outcome |

|---|---|---|---|

| Concept Development | Collaborating with clients on initial designs. | Brainstorming sessions, sketches, and material selection. | Clear design direction based on client needs. |

| Prototyping | Creating initial samples for client review. | Rapid prototyping and material testing. | Received feedback for refinements before production. |

| Production Planning | Finalizing designs and preparing for manufacturing. | Scheduling, sourcing, and setting up production lines. | Efficient production workflow established. |

| Manufacturing | Producing the final floor mats. | Quality control and assembly line operations. | High-quality finished products ready for delivery. |

| Delivery | Shipping the products to clients. | Logistics planning and coordination. | On-time delivery ensuring customer satisfaction. |