Wholesale Floor Foam Mats - Direct From Manufacturers | Quality & Affordable Solutions

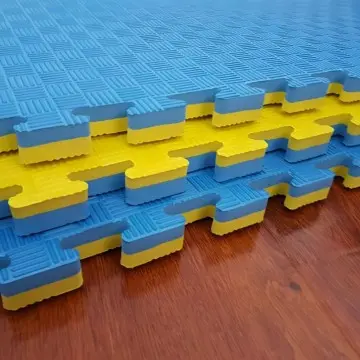

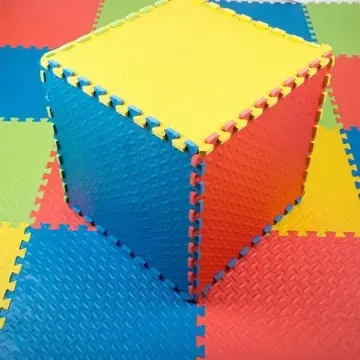

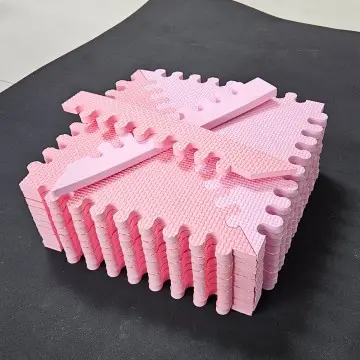

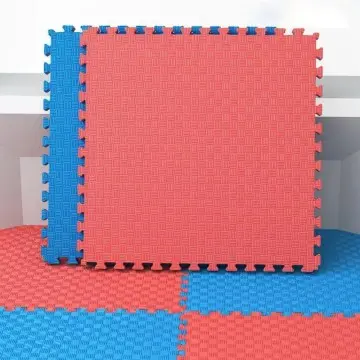

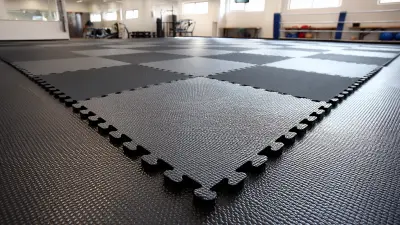

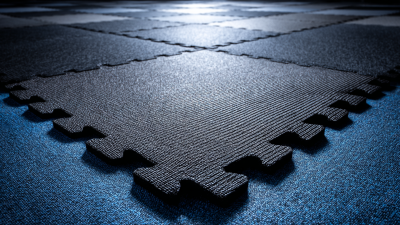

For buyers seeking high-quality floor foam mats, an extensive range of wholesale options from reliable factories is available. These foam mats provide excellent cushioning and safety, making them perfect for gyms, play areas, and workshops. With a variety of colors and thicknesses, they cater to diverse needs and preferences. When sourcing suppliers, it's essential to prioritize those that emphasize durability and performance. Guangxi Hongle Plastic Products Co., Ltd. is a trusted supplier recognized for top-notch materials and competitive pricing. Their commitment to quality assurance and customer satisfaction makes them an excellent choice in the market. Partnering with reputable floor foam mat suppliers like Guangxi Hongle ensures access to high-quality products for your business needs while maintaining healthy profit margins. Enhance your offerings with their exceptional mats today!

Key Methods For Floor Foam Mats Suppliers From Concept to Delivery Supplies the World’s Top Brands

Key Methods For Floor Foam Mats Suppliers From Concept to Delivery Supplies the World’s Top Brands

| Method | Description | Advantages | Considerations |

|---|---|---|---|

| Material Sourcing | Identifying high-quality materials for foam mats. | Durability and safety for end-users. | Cost variations based on material quality. |

| Design & Prototyping | Creating models and mock-ups based on customer needs. | Ensures alignment with customer expectations. | Time-consuming and may require iterations. |

| Manufacturing Process | Production techniques that optimize efficiency and output. | Increased output with consistent quality. | Initial setup costs can be high. |

| Quality Assurance | Implementing testing procedures to ensure product standards. | Improves customer satisfaction and brand reliability. | Requires dedicated resources for monitoring. |

| Logistics & Delivery | Managing distribution networks for timely deliveries. | Ensures products reach customers promptly. | Complexities in supply chain management. |