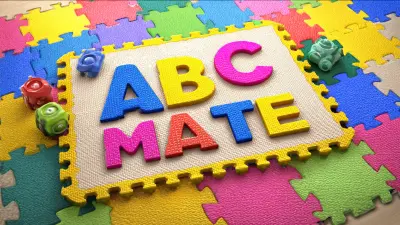

Wholesale Foamed Flooring | Top Manufacturers & Superior Quality Solutions

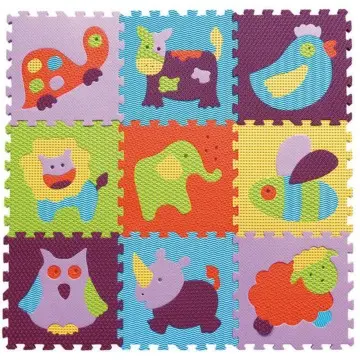

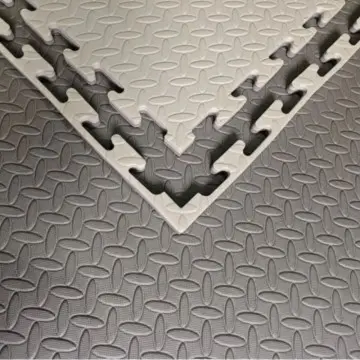

At our **Foamed Floor Factory**, we provide top-quality, durable flooring solutions designed to meet a variety of needs. As a trusted manufacturer and supplier, we offer wholesale options suitable for businesses of all sizes. Our products are built to endure heavy use, making them ideal for commercial spaces, warehouses, and beyond. With years of industry experience, we focus on delivering not just exceptional products but also outstanding service. We prioritize your satisfaction through customized orders and prompt deliveries. Choose us for your flooring solutions and experience the advantages of partnering with a dedicated supplier. Contact us today to learn more about how we can support your flooring needs!Best Practices For Foamed Floor Factory Where Innovation Meets 2025 From Concept to Delivery

In the ever-evolving landscape of manufacturing, particularly within the production of innovative foamed flooring solutions, understanding best practices becomes essential for global suppliers. As we look ahead to 2025, it’s crucial to focus on bridging the gap between concept and delivery. The journey begins with a proactive approach to product development. Engaging in thorough market research helps identify emerging trends, allowing manufacturers to innovate while aligning with the needs of diverse clients. Furthermore, investing in advanced technological capabilities is vital. Automation and smart manufacturing processes streamline production, enhance efficiency, and ensure consistency in quality. This not only meets the growing demands of international procurement but also solidifies a reputation for reliability in the competitive global market. A commitment to sustainability and eco-friendly materials can also set a manufacturer apart, appealing to eco-conscious buyers who prioritize sustainable sourcing in their procurement decisions. Lastly, fostering strong relationships with global partners through transparent communication and collaborative processes is essential. Being responsive to client feedback and adapting swiftly to their needs can significantly enhance customer satisfaction and loyalty. As we approach 2025, these best practices will not only propel manufacturers toward growth but also ensure that they remain at the forefront of the foamed flooring industry, delivering innovative solutions that meet and exceed market expectations.

Best Practices For Foamed Floor Factory Where Innovation Meets 2025 From Concept to Delivery

| Dimension | Description | Best Practice | Expected Outcome |

|---|---|---|---|

| Material Selection | Choosing high-quality raw materials for foamed floor production. | Conduct thorough supplier audits and sample testing. | Increased product durability and customer satisfaction. |

| Innovation Integration | Incorporating new technologies in the manufacturing process. | Adopt automation and IoT technologies. | Enhanced efficiency and reduced time to market. |

| Quality Control | Implementing strict quality assurance protocols. | Regular training sessions for quality management teams. | Minimized defects and enhanced reputation. |

| Sustainability Practices | Using eco-friendly materials and manufacturing methods. | Ensure compliance with environmental regulations. | Improved marketability and customer loyalty. |

| Customer Feedback | Gathering customer insights for product improvement. | Implement a systematic feedback collection process. | Products that meet customer demands and trends. |

Making Smart Choices Foamed Floor Factory Custom Solutions, More Than a Supplier - A Partner

J

Jackson Hall

Outstanding quality! The staff were friendly and took the time to answer all my questions.

12 May 2025

S

Scarlett Ortiz

I am very impressed! The product surpassed my expectations, and service was friendly and supportive.

06 June 2025

J

James Clark

The quality is stellar! The after-sales service really made my experience worthwhile.

19 June 2025

H

Henry Bell

The product quality is impressive! The after-sales team was attentive and thorough.

05 July 2025

P

Peyton Martinez

Product quality is excellent! The customer care team was attentive and responsive.

27 June 2025

S

Sophie Wood

Impressive quality! The information and support from the team were invaluable.

03 June 2025