Export Guide for EVA Foam Play Mats: Certifications and Quality Control Process

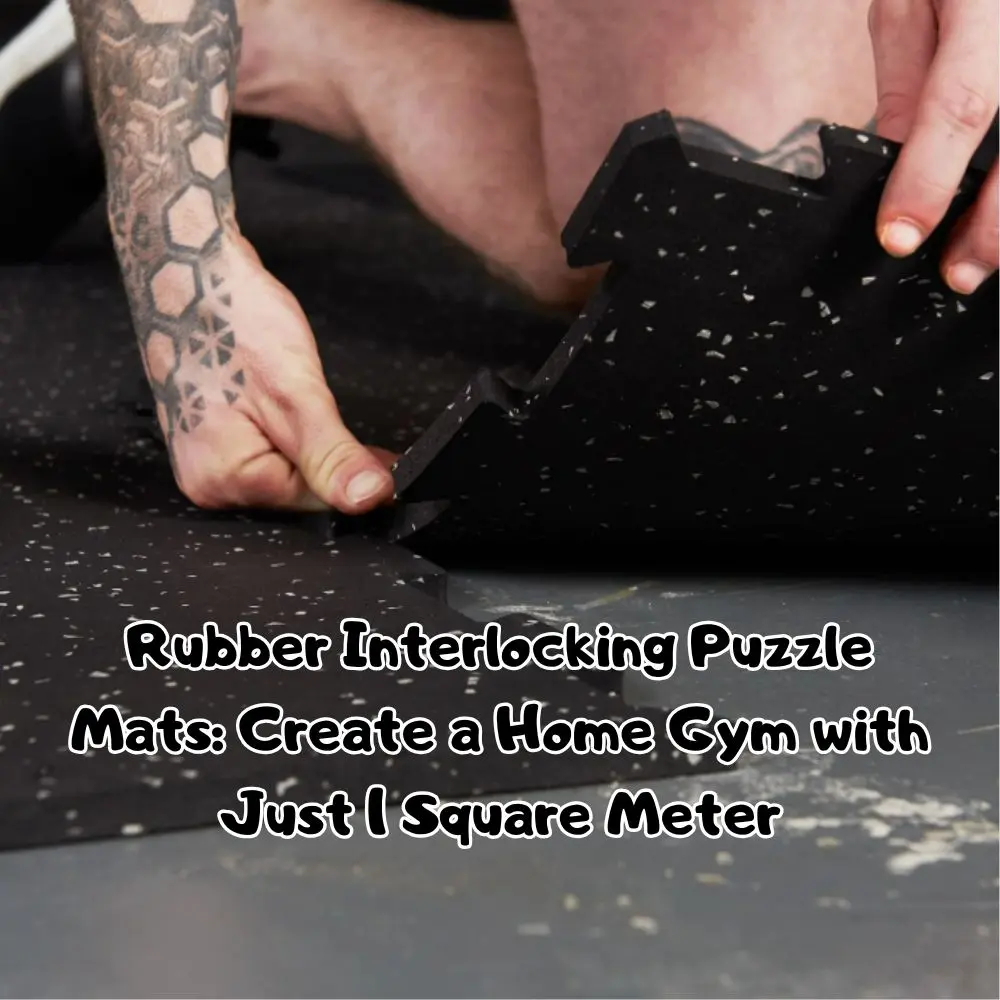

With the growing global demand for children's products, EVA foam play mats have become a popular item in wholesale and retail markets due to their lightweight, soft texture, colorful design, and ease of installation. For importers and sourcing agents, understanding the necessary compliance standards and factory quality control procedures is essential to ensure smooth customs clearance and consistent supply.

✅ 1. Common Certifications for Exporting Children’s EVA Mats

Different countries and regions require specific safety standards for children's EVA products. Here's a quick overview:

| Market | Certification | Key Focus |

|---|---|---|

| EU | EN71 Part 1/2/3 | Mechanical safety, flammability, heavy metal migration |

| EU | REACH | Control of SVHC substances (e.g., formamide, phthalates) |

| USA | CPSIA, ASTM F963 | Limits on lead, phthalates, labeling requirements |

| UK | UKCA (aligned with EN71) | Post-Brexit compliance for the UK market |

| Others | Optional: CA Prop 65, ISO8124, etc. | Based on client’s specific market needs |

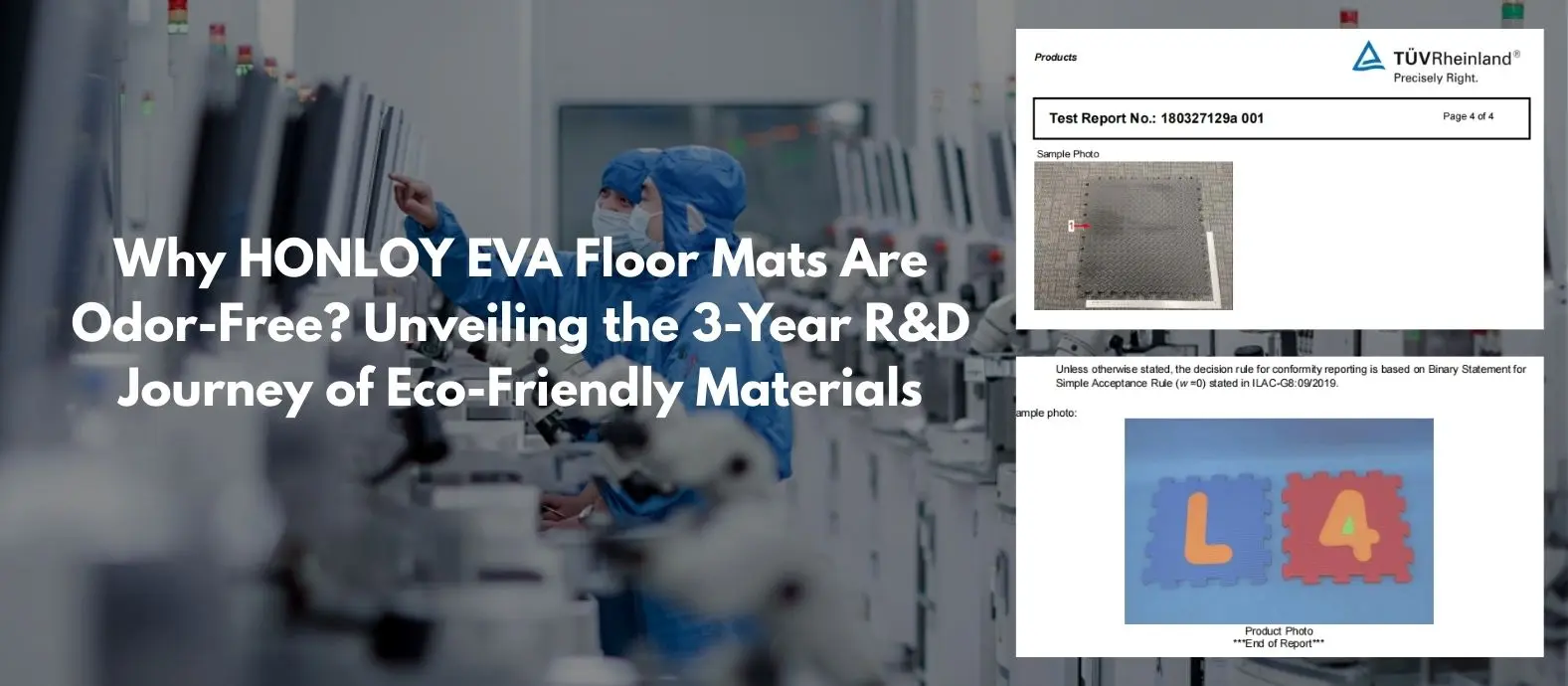

📌 Our EVA Play Mats comply with EN71, CPSIA, and other essential certifications. Third-party testing (SGS, TÜV, BV, etc.) can be arranged upon request with full test reports.

Passed the Formamide Test.

🧪 2. Key Compliance Factors for EVA Foam

For children’s floor mats, the following substances and safety aspects are the most commonly regulated:

-

Formamide: Strict limits under EU REACH

-

Phthalates: Common in plasticizers; restricted by CPSIA

-

Heavy Metals: Lead, cadmium, chromium, etc. under EN71-3

-

Printing Inks: Should be non-toxic and safe for children

We use eco-friendly EVA material with non-toxic heat-press molding and child-safe printing inks that meet food-grade safety standards.

🏭 3. Quality Control Process & Stable Production

With years of experience in EVA mat manufacturing, our factory follows a strict QC workflow to ensure consistent quality:

-

Raw Material Check: Each EVA batch is pre-tested for RoHS/REACH compliance

-

In-Process Sampling: Random checks for thickness, weight, fit, and print clarity

-

Final Product Inspection: Verifying packaging, accessories, and product integrity

-

Regular Third-Party Audits: To maintain batch consistency and trustworthiness

Full QC reports and pre-shipment video confirmations are available for bulk orders.

🎯 4. Tips for Custom Orders: Plan Certification Early

If you plan to customize designs (e.g., color, shape, packaging), we recommend considering the following in advance:

-

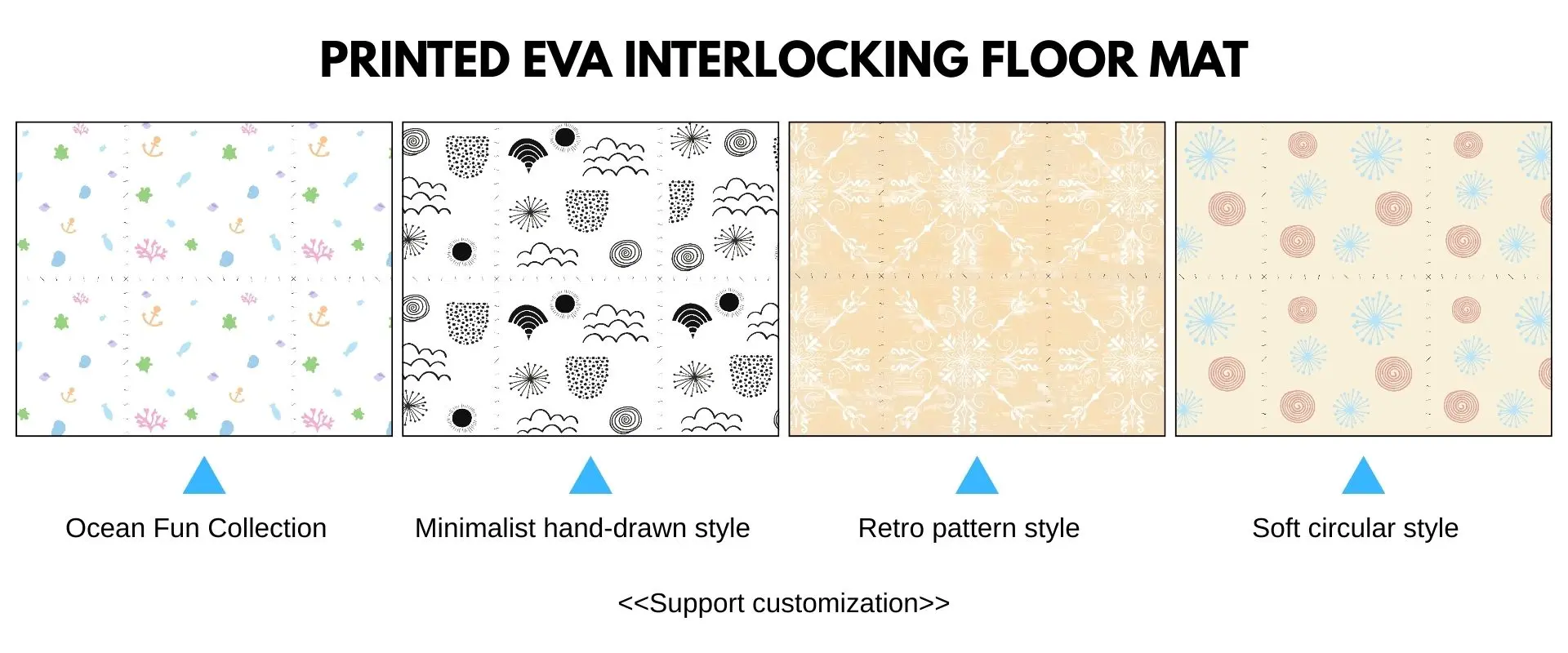

Avoid overly intricate patterns that may not mold clearly

-

Confirm ink safety and colorfastness if printing is involved

-

Decide if packaging needs user manuals or translated content

-

Notify us early about specific labeling needs (e.g., CE mark, tracking labels)

Early communication helps us streamline production and arrange any required testing in advance.

Conclusion

Children’s EVA play mats are a high-potential export category—but safety standards are strict. Choosing a factory with proven compliance experience and solid quality control can save time, costs, and hassle in the long run.

We welcome global wholesale buyers to request samples, visit our factory, or start a custom design project together.

📧 Contact us for test report samples, wholesale pricing, and our latest product catalog.