Standard Operating Procedures for Container Loading and Inspection of EVA Foam Puzzle Mats

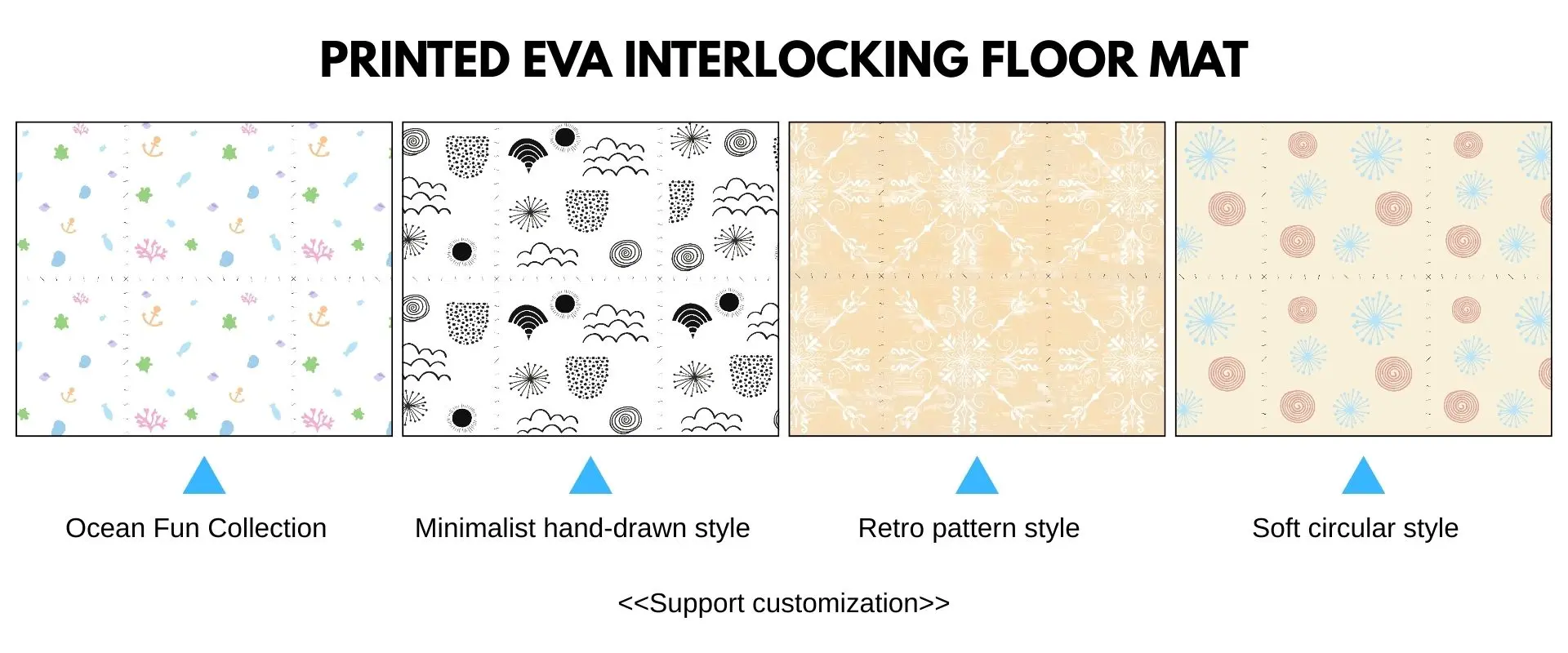

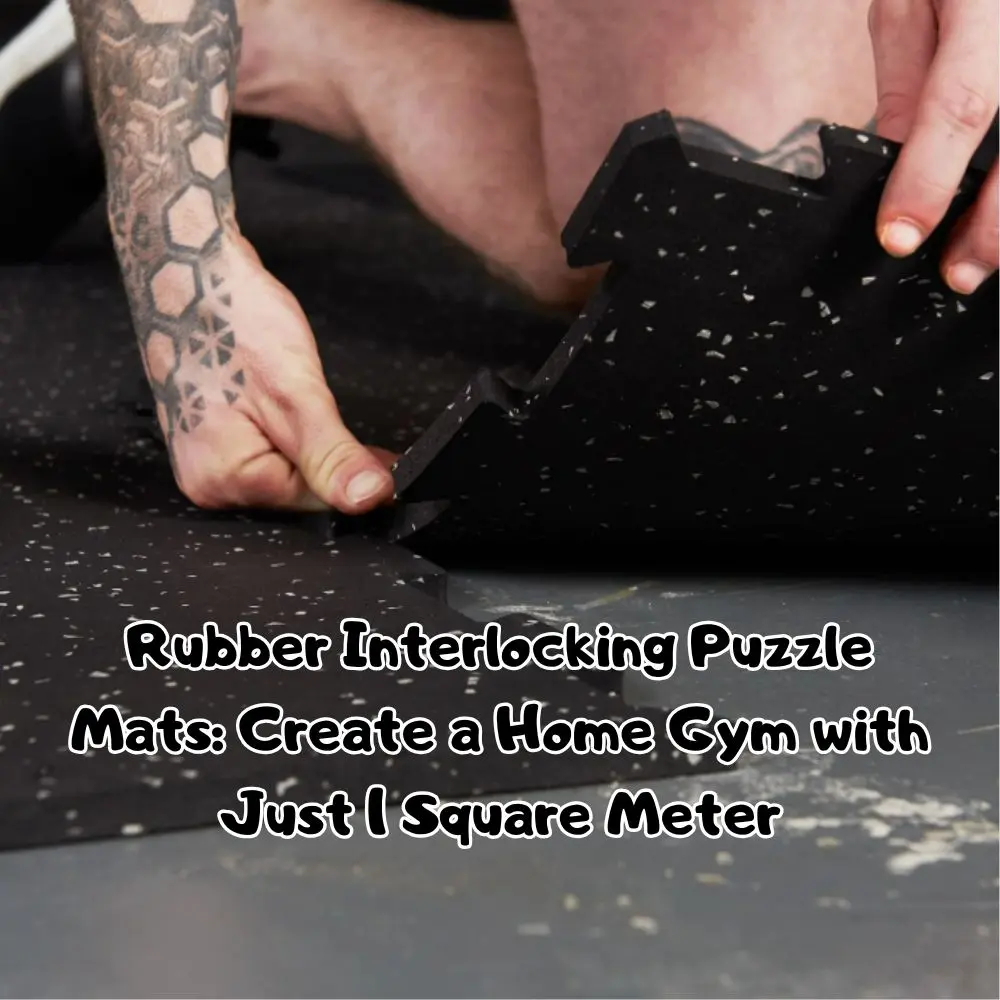

As a trader specializing in the production and export of EVA foam puzzle mats, children's play mats, fitness exercise mats, and martial arts floor mats, HONLOY recognizes that the container loading process is directly linked to cargo transportation safety, delivery efficiency, and customer satisfaction. After the factory completes production and delivers the goods to the designated port, professional port staff must strictly adhere to standardized loading procedures. This ensures that each batch of products is safely, compliantly, and efficiently loaded into containers, laying a solid foundation for the international transportation of goods.💕💕💕

1️⃣. Factory Shipment Preparation

1.1 Product Inspection

Prior to shipment, each batch of mat products must undergo rigorous inspection to ensure quality complies with order requirements, with no damage, deformation, stains, or other quality defects.

1.2 Packaging Reinforcement

Appropriate packaging materials should be used for product packaging. For puzzle-type products, ensure all puzzle pieces are complete and the packaging is secure to prevent scattering during transportation.

1.3 Clear Labeling

Each package must be clearly labeled with product name, specifications, quantity, order number, and other information to facilitate subsequent loading, unloading, and inventory checks.

2️⃣. Transportation Requirements

2.1 Vehicle Selection

Select appropriate transport vehicles based on cargo volume and transportation distance. Ensure vehicles have good driving performance and are equipped with rainproof and moisture-proof facilities.

2.2 Loading Method

During loading, handle the mat products with care to avoid compression and collision. Plan the vehicle space rationally and sort products of different specifications and orders separately to facilitate unloading and container loading at the port.

2.3 Transportation Monitoring

During transportation, real-time monitoring of vehicles can be conducted via GPS tracking to ensure goods arrive at the port on time and safely.

3️⃣. Specifications for Container Loading

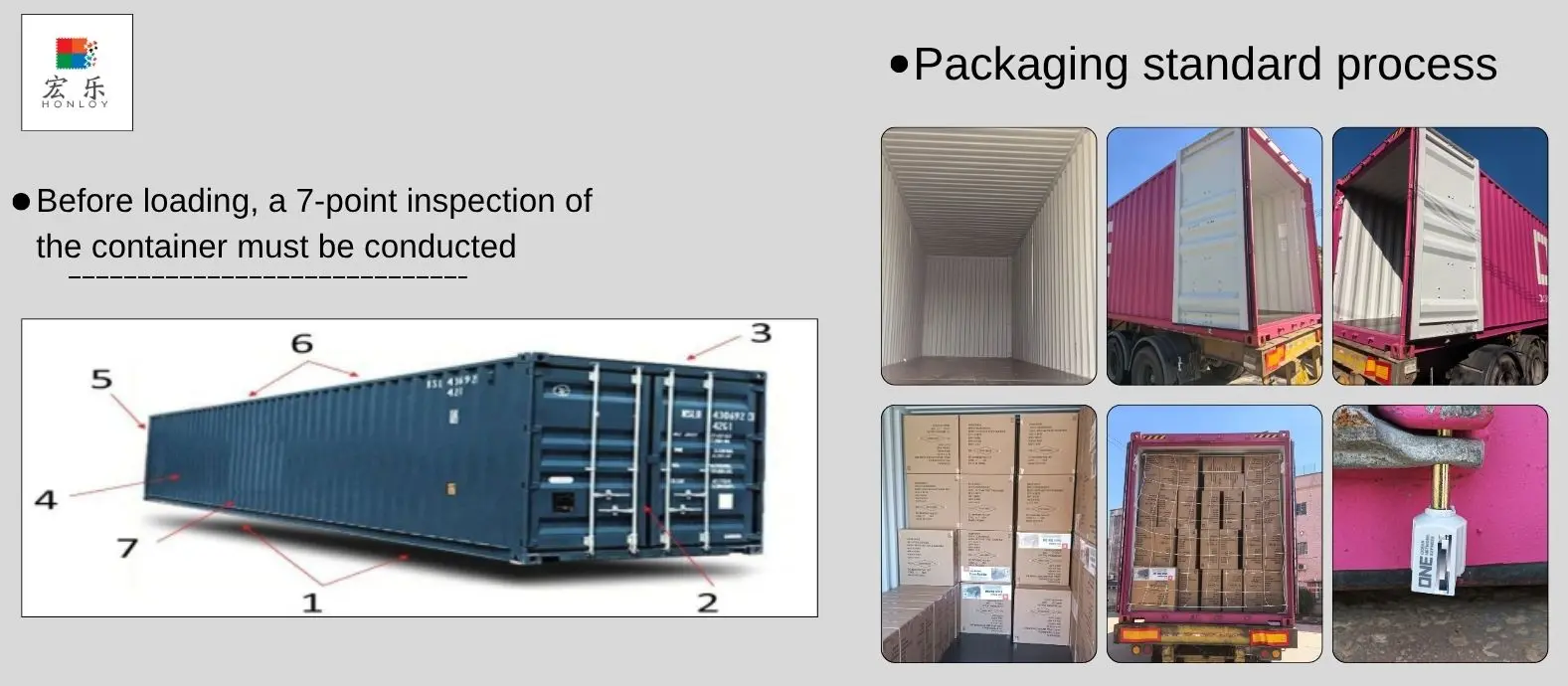

3.1 Container Inspection (7-Point Check)

Before loading, a mandatory 7-point inspection of the container must be conducted:

- Container Chassis: Verify visibility of support frames and confirm compliance before loading.

- Inside/Outside of Doors: Inspect door locks for security; ensure no mismatched material patches, loose bolts, holes/cuts, or rust.

- Right Side Panel: Check beam structure for abnormal repairs (internal wall repairs must be visible externally); confirm no holes/cuts, dents, or rust; tap to ensure no hollow sound and surface dryness.

- Left Side Panel: Follow the same inspection standards as the right side panel.

- Front Wall: Ensure corner blocks and ventilation holes are visible; tap lightly with a tool to confirm no hollow sound.

- Ceiling/Top: Verify consistent height from the ground; check visibility of blocks and ventilation holes (no unusual sensations); confirm internal repairs are externally visible, no hollow sound when tapped, no holes/cuts, dents, or rust, and surface dryness.

- Floor: Ensure consistent height from the ceiling and flatness; confirm no unevenness, abnormal repairs, or oil stains; ensure clean and dry conditions.

3.2 Loading Operations

- Loading Sequence: Arrange based on product characteristics and destination requirements (heavier/larger items at the bottom; fragile/deformable items on top).

- Gap Filling: Use foam, cardboard, or similar materials to fill gaps between goods, preventing movement and collision during transportation.

- Cargo Securing: For large-volume or rollable goods, apply securing measures (e.g., rope binding, steel strapping).

4️⃣. Post-Loading Inspection Standards

After loading completion, staff must perform strict quality control and document organization:

4.1 Cargo Inspection

- Quantity Verification: Recheck loaded cargo quantity to ensure alignment with orders and loading plans.

- Cargo Condition Inspection: Check for damage or deformation caused during loading; record issues promptly and implement remedial measures.

4.2 Container Sealing Inspection

- After closing container doors, verify tight sealing; apply a lead seal and accurately record the seal number on documents (e.g., packing list, bill of lading).

- Attach cargo labels to the container exterior, indicating product name, quantity, destination, fragile marks, and other information to facilitate handling and inspection during transportation.

4.3 Documentation and Signature Confirmation

- Loading Records: Document details including loading time, cargo status, and container inspection results.

- Organize and file documents (packing lists, cargo manifests, seal records); submit to freight forwarders and customers promptly to ensure smooth customs declaration/clearance and provide complete documentary support for delivery.

- Signature Confirmation: Driver and on-site supervisor must sign loading records to confirm responsibility.

5️⃣. Compliance and Commitment

Strict adherence to each operational step and standard safeguards product quality and upholds customer trust. HONLOY consistently maintains a professional, rigorous approach to standardized loading, ensuring each batch of Eva Mats is delivered safely and on time. We are committed to providing high-quality products and reliable logistics support to global clients.

☎️Phone: +86 13509077236

📧Email: lorraine_lao@honloy.com