Why HONLOY EVA Floor Mats Are Odor-Free? Unveiling the 3-Year R&D Journey of Eco-Friendly Materials

"Strong pungent plastic smell right after unpacking" "Still irritating even after airing for a week" — these are common complaints about most Eva Floor Mats on the market. In stark contrast,HONLOY EVA floor mats only emit a faint, natural material scent from unpacking to daily use, barely noticeable even when smelled up close. Behind this remarkable difference lies a 3-year R&D campaign dedicated to developing eco-friendly materials by the HONLOY team.🏭

Step 1: Eliminating Odor Sources at the Raw Material Stage with Food-Grade EVA Pellets🌺

The unpleasant odor of ordinary EVA floor mats mostly stems from impurities in low-quality raw materials. Cheap EVA pellets are often mixed with recycled plastics and plasticizers, which release harmful gases like formaldehyde and VOCs during the heating and foaming process.

The R&D team’s first priority was to "take a hard line on raw materials": only food-grade high-purity EVA pellets (with VA content strictly controlled between 18% and 20%) are selected. These pellets are inherently odorless and free of heavy metals, and suppliers must provide SGS non-toxicity test reports to qualify for HONLOY’s raw material procurement list. To ensure stable supply and consistent quality, the team has signed exclusive supply agreements with 3 international suppliers. Every batch of raw materials undergoes double inspections: blind odor testing and component analysis.

Step 2: A Revolution in Foaming Technology: From High-Temperature Rapid Foaming to Low-Temperature Slow Foaming👣

Traditional EVA foaming relies on a "high-temperature and high-pressure rapid molding" process. High temperatures cause trace impurities in the raw materials to decompose, producing offensive odors — the reason why many floor mats smell worse when exposed to heat.

The HONLOY team spent 1 year overhauling the foaming process, switching to a low-temperature slow foaming + segmented temperature control method. The foaming temperature was reduced from 180℃ to 140℃, and the foaming time was extended from 3 minutes to 12 minutes. This gradual heating allows EVA pellets to fuse fully while preventing the decomposition of impurities. After foaming, the mats are placed in a constant-temperature curing chamber for 72 hours to allow residual trace gases to volatilize naturally. Although this process increases production costs by 20%, it fundamentally eliminates odor at the source.

As the head of the production team stated: "We conducted tests showing that ordinary floor mats can cause formaldehyde concentrations to exceed the standard by 3 times in a closed space within 2 hours. In contrast, the formaldehyde concentration of HONLOY mats remains less than 1/5 of the national standard after curing, with only a subtle natural EVA scent detectable upon close inspection."

Step 3: Glue-Free Splicing & Full-Lifecycle Odor Testing to Prevent Secondary Odor Pollution💖

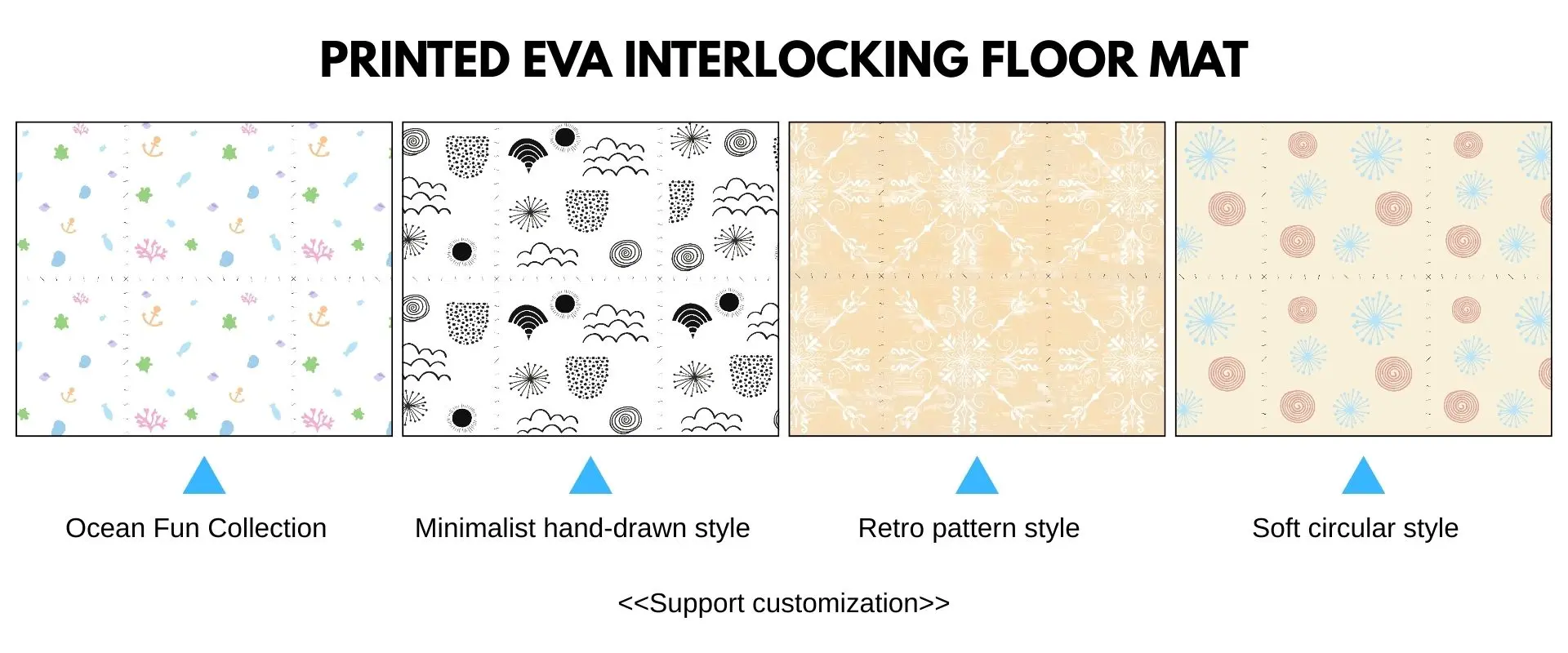

Many floor mats are odorless on their own, but the glue used for splicing introduces new unpleasant smells. HONLOY adopted an interlocking buckle design instead of glue, eliminating odor risks from adhesives at the design stage. Additionally, the mat printing process uses heat transfer printing rather than ink spraying. High-temperature transfer ensures that patterns fuse deeply with the material, avoiding the release of solvent-based odors.

Furthermore, HONLOY has established a full-lifecycle odor testing system:

- During Production: Foamed semi-finished products are randomly inspected every hour, with VOC content measured using professional odor detectors.

- Before Factory Shipment: Each batch of mats is placed in a 30㎡ sealed chamber for 24 hours, and only those that pass the air quality test of the chamber are allowed to leave the factory.

- Before Export: Additional testing is conducted in compliance with the EU REACH Regulation, screening for 197 high-concern substances to ensure that overseas customers can also use odor-free floor mats.

The original aspiration of the HONLOY team is simple: "Many families buy EVA floor mats for their babies, who may chew or crawl on them. We must ensure that our mats are safe enough for babies to bite." Today, HONLOY floor mats have not only obtained international eco-certifications including EU CE and US ASTM but have also become the designated choice for numerous mother-and-baby stores and early education centers.🥇

From raw material selection to process innovation, from comprehensive testing systems to thoughtful design details, the odor-free feature of HONLOY EVA floor mats embodies the commitment to environmental safety of a 20-year professional manufacturer. After all, for families, being odor-free is never a bonus feature — it is the basic requirement for a floor mat. And HONLOY is determined to exceed this standard with exceptional safety.👍

Phone: +86 13509077236

Email: lorraine_lao@honloy.com

Web: https://site_d5e27c30-4ecf-4b3c-bcb2-77b1a43faa65/