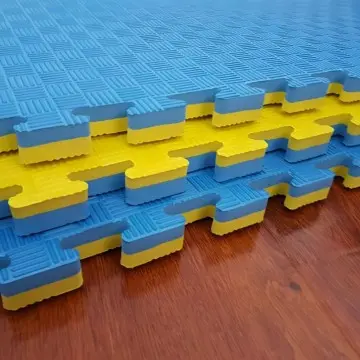

OEM Foam Floor Mats for Babies - Premium Quality from Leading Manufacturers

As a trusted provider of OEM Foam Floor Mats for babies, our focus is on ensuring safety and comfort for your little ones. Our mats are crafted from high-quality, non-toxic materials, creating a secure play environment for infants and toddlers. With superior cushioning and support, they are ideal for crawling, playing, or resting. We offer customizable options to meet your brand's specific needs, including colors, designs, and sizes. With years of expertise, partnering with Guangxi Hongle Plastic Products Co., Ltd. guarantees exceptional service and consistent quality, making us a reliable choice for your business.Best Methods To OEM Foam Floor Mat For Baby Service Products

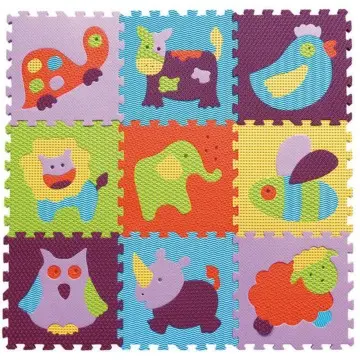

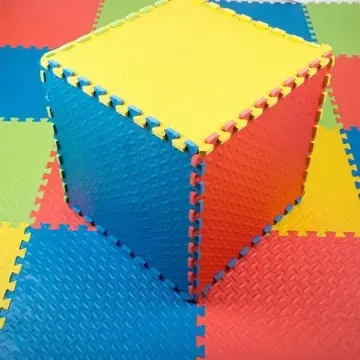

When considering the best methods to OEM foam floor mats for baby service products, it is essential to focus on quality, safety, and design. The first step involves selecting high-quality materials, such as EVA foam, known for its durability and non-toxic properties. This not only assures parents of the safety of their children but also enhances the longevity of the product. Successful OEM partnerships leverage advanced production techniques that ensure consistency in material quality, providing an edge in today's competitive market. The design phase is equally crucial. Customization options should reflect the aesthetic preferences of target markets, incorporating vibrant colors and engaging patterns that stimulate children's development and creativity. Additionally, offering various thickness levels and textures can cater to different customer needs, from Play Mats to exercise areas. Collaborating closely with OEM partners to align on design specifications can result in products that stand out in the market. Finally, effective logistics and supply chain management are vital for timely delivery and maintaining quality standards. Establishing strong relationships with reliable suppliers and manufacturers can streamline production processes, ensuring that every mat meets stringent safety regulations and customer expectations. By focusing on these strategic areas, businesses can successfully enter the growing demand for baby service products, ensuring a positive impact on both children’s safety and parental peace of mind.

Best Methods To OEM Foam Floor Mat For Baby Service Products

| Method | Description | Advantages | Disadvantages |

|---|---|---|---|

| Injection Molding | A process where foam is injected into a mold to create customized shapes and designs. | High precision, scalability, and ability to create complex shapes. | Higher initial tooling costs and longer setup time. |

| Die Cutting | A method where foam sheets are cut into specific shapes using a die. | Cost-effective for large volumes and quick turnaround times. | Limited to 2D shapes and may not be as customizable. |

| Compression Molding | Foam material is compressed in a mold to achieve the desired thickness and shape. | Excellent for creating thicker mats and can reduce material waste. | May be slower than other methods and can require more energy. |

| Waterjet Cutting | A process using a high-pressure water jet to cut foam into desired shapes. | High precision and no heat-affected zones, allowing for intricate designs. | Can be more expensive than traditional cutting methods. |

| CNC Routing | Using a computer-controlled router to precisely cut foam mats. | High accuracy and flexibility for complex designs. | Setup and programming can be time-consuming and costly. |

Top 3 OEM Foam Floor Mat For Baby From Concept to Delivery Application

N

Noah Thomas

I highly recommend this product. The after-sales service is remarkable, making the entire experience smooth.

23 June 2025

C

Charlotte Harris

Fantastic experience! The quality is just as promised, and the service was very professional.

28 June 2025

L

Lucy Perez

Delightful purchase experience! Superb quality and an attentive support team.

19 May 2025

E

Ethan Hayes

Great product! The quality is outstanding, and the service team was very professional.

25 June 2025

C

Charlotte Hunter

Impressive product quality! Their support team handled my inquiries with thoroughness.

01 June 2025

K

Kylie Ramirez

Amazing quality! The staff are well-trained and addressed my inquiries promptly.

20 June 2025