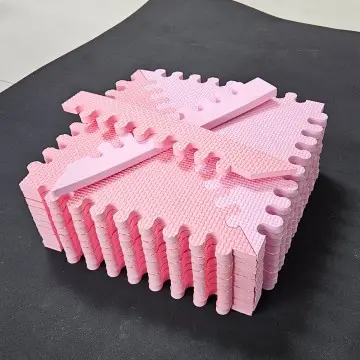

OEM Locking Foam Mats - Reliable Suppliers & Factories | Buy High-Quality Today!

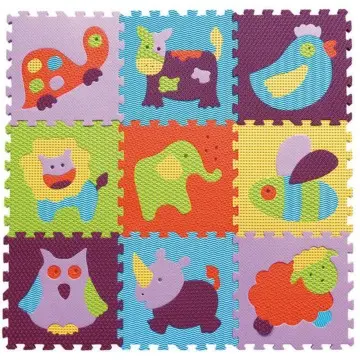

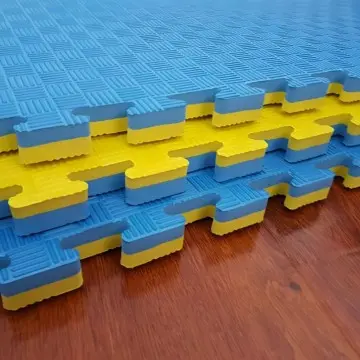

As a seasoned professional in the industry, I recognize the need for quality and reliability in OEM Locking foam mats. Our diverse selection of mats is suited for a variety of applications, including gyms, play areas, and specialized flooring. We source our products directly from trusted suppliers, ensuring exceptional durability and performance. Partnering with Guangxi Hongle Plastic Products Co., Ltd. means collaborating with a manufacturer dedicated to excellence. Our foam mats not only enhance spaces but also prioritize safety and comfort. For wholesale opportunities, we offer competitive pricing and flexible order quantities, providing excellent value for your next project.Methods To OEM Locking Foam Mats Supplier Service

When it comes to sourcing OEM locking foam mats, partnering with a reliable supplier is crucial for ensuring quality and consistency. As a key player in the industry, a supplier’s expertise in the production of high-quality EVA foam products is essential for meeting diverse market demands. Understanding the methods that suppliers utilize to ensure excellence in their OEM services can help global buyers make informed decisions. One effective method that reputable suppliers employ is a rigorous quality control process throughout the production cycle. From the selection of raw materials to the final product inspection, each stage is meticulously monitored to ensure that every foam mat meets the highest standards. Additionally, leveraging advanced technological capabilities enables manufacturers to innovate and customize products tailored to specific requirements, whether for sports, play areas, or industrial applications. Furthermore, establishing open lines of communication with suppliers allows for better collaboration and responsiveness. A proactive approach to addressing client needs not only leads to enhanced product development but also fosters long-term partnerships. Buyers are encouraged to evaluate potential suppliers based on their production expertise, quality assurance practices, and commitment to customer service to secure a reliable source for OEM locking foam mats.

Methods To OEM Locking Foam Mats Supplier Service

| Method | Description | Advantages | Considerations |

|---|---|---|---|

| Compression Molding | A method that uses heat and pressure to shape foam into mats. | High durability, efficient for mass production. | Requires significant equipment investment. |

| CNC Cutting | Utilizes computer-controlled machines to cut foam mats from larger sheets. | Precision cutting, customizable designs available. | Higher costs for small production runs. |

| Laminate Bonding | Adhesively bonding multiple foam layers or materials together. | Flexible material properties, can create various textures. | Adhesive quality can affect durability. |

| Injection Molding | Injecting foam material into molds to create shapes. | Ideal for complex shapes, high production efficiency. | Initial mold costs can be high. |

| Die Cutting | Using a die to cut out specific shapes from foam sheets. | Cost-effective for high quantity runs. | Limited to designs that fit within the die. |

How Chinese Manufacturers OEM Locking Foam Mats Industry Giant Where Innovation Meets 2025

H

Henry Bell

The product quality is impressive! The after-sales team was attentive and thorough.

05 July 2025

J

Jackson Gonzales

Fantastic quality! Their support team was very professional, ensuring all my needs were met.

29 May 2025

C

Charlotte Hunter

Impressive product quality! Their support team handled my inquiries with thoroughness.

01 June 2025

A

Ava Ramirez

Incredible product! Excellent after-sales service, which shows their dedication to customers.

27 May 2025

W

Wyatt Morales

Amazing experience! The quality is fantastic, and the service team was prompt.

31 May 2025

E

Eli Bennett

Wonderful experience! The product exceeded my expectations, and the service was superb.

13 June 2025