OEM Soft Floor Tiles Manufacturer | Quality Factory Direct Solutions at Competitive Prices

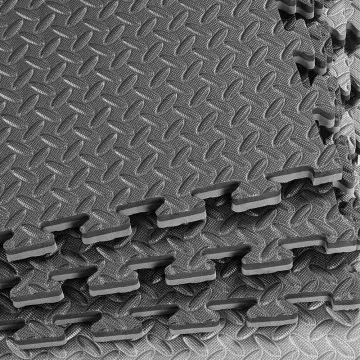

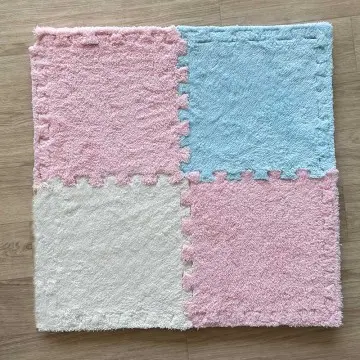

As a foremost manufacturer of soft floor tiles, I prioritize the delivery of high-quality flooring solutions tailored to the varying needs of different industries. Our OEM services support factories and suppliers by providing durable, stylish, and easy-to-install tiles. With extensive experience in the field, I am dedicated to producing products that enhance both aesthetics and functionality. At Guangxi Hongle Plastic Products Co., Ltd., innovation and sustainability are at the core of our ethos, ensuring our tiles are crafted from eco-friendly materials that endure over time. Whether you are a large-scale factory in need of bulk supply or a supplier seeking reliable flooring options, I aim to foster collaboration that supports your business growth. Count on me for exceptional service and premium floor tiles designed to elevate your projects and create lasting impressions.Practical Strategies for Soft Floor Tiles Manufacturer Application From Concept to Delivery

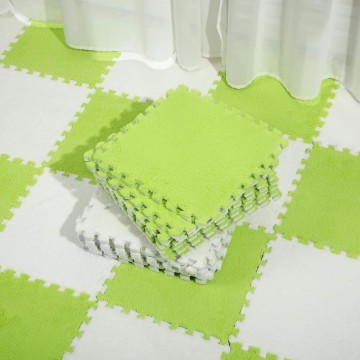

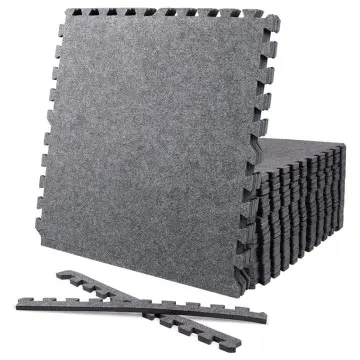

In the competitive landscape of flooring solutions, navigating the journey from concept to delivery can be daunting for manufacturers of soft floor tiles. However, by adopting practical strategies, companies can effectively streamline their process and cater to the international demand for high-quality products. The first step is to leverage advanced technological capabilities during the design phase. Utilizing 3D modeling and simulation tools can facilitate the creation of innovative patterns and textures, ensuring products meet aesthetic and functional requirements. Collaborating with experienced designers and industry experts can further enhance creativity while adhering to manufacturing efficiencies. Once the design is finalized, rigorous material selection is crucial. High-quality EVA foam, known for its durability and resilience, serves as an excellent choice for soft floor tiles. It’s essential to conduct thorough testing to ensure the materials used align with safety regulations and performance standards in various markets. Efficient logistics and supply chain management can then ensure timely delivery, meeting the time-sensitive demands of global customers. By focusing on consistency in quality, effective communication, and responsiveness, manufacturers not only fulfill customer expectations but also build long-lasting partnerships and enhance their brand reputation in the global marketplace.

Practical Strategies for Soft Floor Tiles Manufacturer Application From Concept to Delivery

| Strategy | Description | Implementation Steps | Expected Outcome |

|---|---|---|---|

| Market Research | Understanding customer needs and market trends. | Surveys, focus groups, competitor analysis. | Identify target demographic and product features. |

| Product Development | Designing tiles with desired aesthetics and functionality. | Prototyping, testing materials, and design iterations. | Create a product line that meets customer expectations. |

| Supply Chain Management | Optimizing the logistics of materials sourcing and distribution. | Establish relationships with suppliers, streamline inventory. | Reduce costs and improve delivery times. |

| Quality Assurance | Ensuring products meet industry standards and customer expectations. | Regular inspection, feedback loops, compliance checks. | Higher customer satisfaction and reduced returns. |

| Marketing Strategy | Promoting products to reach a wider audience. | Digital campaigns, trade shows, direct sales outreach. | Increase brand awareness and sales volume. |

| Customer Feedback System | Collecting and analyzing customer insights post-purchase. | Surveys, online reviews, follow-up calls. | Continuous improvement in products and services. |

Today's Choice of Soft Floor Tiles Manufacturer Where Innovation Meets 2025 Custom Solutions,

O

Olivia Brown

Excellent quality and even better support. The representatives were professional and attentive to my needs.

13 June 2025

G

George Sanders

The craftsmanship is excellent! I was pleased with how efficiently my questions were answered.

13 June 2025

S

Sadie Bailey

Incredible quality and superior after-sales support. Highly recommended!

31 May 2025

J

Jackson Gonzales

Fantastic quality! Their support team was very professional, ensuring all my needs were met.

29 May 2025

E

Emily Ray

I’m thrilled with my purchase! Exceptional quality and very supportive customer service.

14 June 2025

L

Levi Walker

Great purchase experience! Quality and service were both stellar!

27 May 2025